Homag

Panel dividing saw SAWTEQ B-130

Top quality at the best possible price: the smallest saw in the HOMAG range is equipped as standard with everything you need for cutting single panels and small batches. The SAWTEQ B-130 panel saw costs hardly any more than a well-equipped sliding table saw, while providing a much more precise and efficient cutting process. This is achieved by proven HOMAG technologies and a clearly perceptible increase in automation and processing capabilities. In short, the SAWTEQ B-130 panel-sizing saw makes it easier than ever for you to ease your way into the world of precision manufacturing.

Reference images

Benefits:

- Saw for single panels and small series

- For newcomers and upgraders: super price, super performance

- Semi-automatic cutting: ergonomic, reliable, efficient

- Extensive standard features: everything you need

Features:

- Pressure beam with large-area pressure zone directly at the cutting line: ensures precise cutting results

- Central side pressure device integrated directly in the saw carriage for short cycle times

- 3 air cushion tables, each 500 mm wide, for easy and gentle panel handling

- All-round protective guard for more storage space under the rear machine table

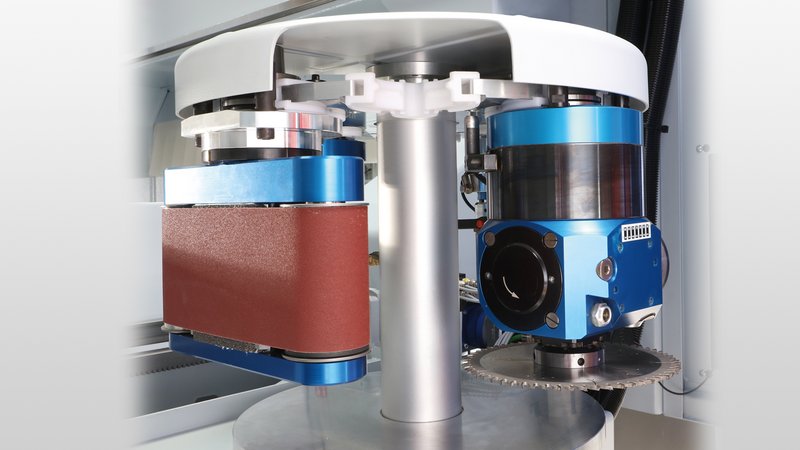

Wide-Belt Sanding Machines SANDTEQ W-100

Whether used as a single-belt machine or with two sanding units, the SANDTEQ W-100 offers an efficient solution for all sanding tasks. This includes calibration and fine sanding of solid wood, as well as sanding of veneers and interim paint sanding (option). Drive outputs of up to 15 kW are available to suit your requirements. The independently driven units also ensure a fast, high-quality results.

Reference images

Benefits:

- The space-saving design means that an installation area of just 5 m² is required

- Excellent sanding results thanks to acp® and eps® pressure beam systems

- Easily adjustable thanks to infinitely variable feed speeds (2-18 m/min)

- High drive outputs of up to 15 kW

- High level of flexibility thanks to independently driven sanding units

- Quiet operation thanks to solid frame construction

Features

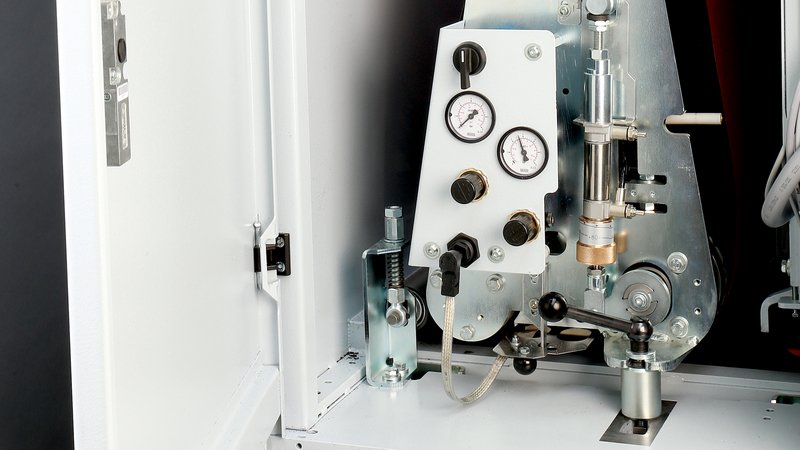

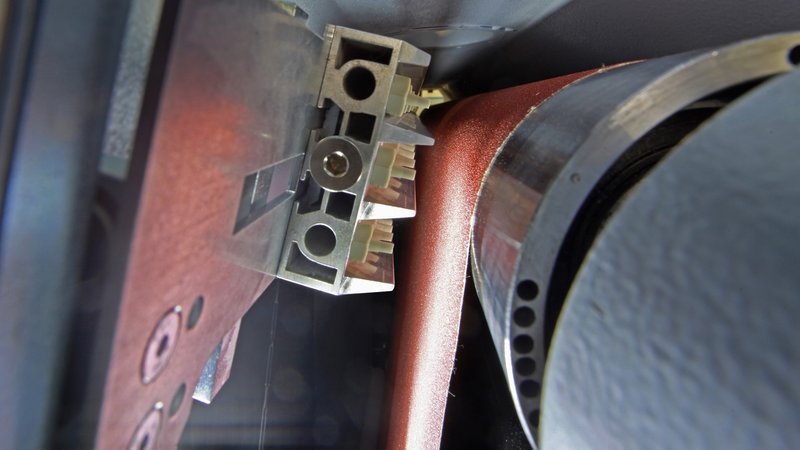

- Fast and safe sanding belt change with robust unit quick-lock function

- Smooth oscillation of the sanding belt thanks to light sensors

- 7" touchscreen operator terminal for machine control

- Stable guiding of workpieces via rubberized contact pressure rollers

- Easier and more precise grain calibration using an adjusting wheel

- High-quality poly-v-belt drive

Shaped part edge banding / post-processing machines

The flexible solution for all shaped parts. Find the right solution for the edging and post-processing of your shaped parts. The EDGETEQ T-200 and EDGETEQ T-100 offer a flexible machine concept, enabling both shaped parts and straight parts to be processed.

Reference images

Benefits:

- The ideal machines for small quantities

- Compact, space-saving machines

- Impressive price-performance ratio

Features:

- Flexible concept for gluing and processing of shaped parts

- Individual table design for processing a wide range of parts

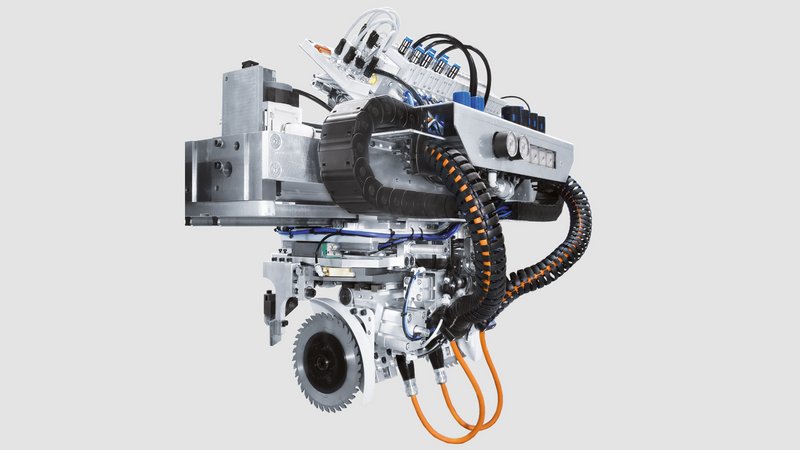

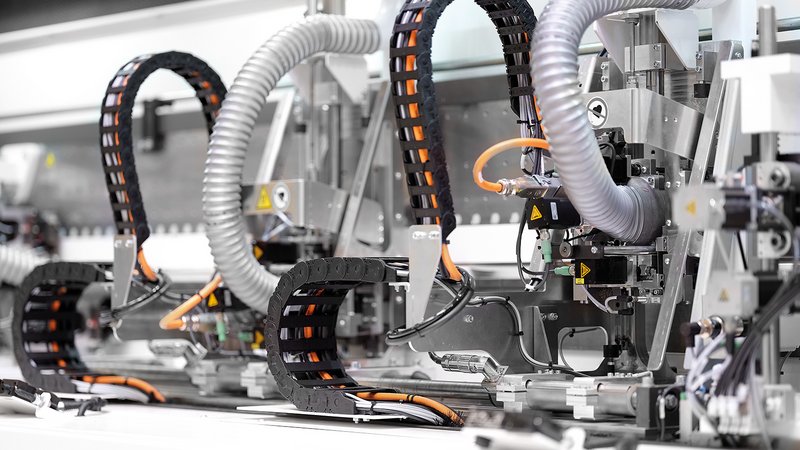

Edge banding machines EDGETEQ S-500 Optimat and profiLine

Comprehensive equipment standard The single-sided EDGETEQ S-500 offer precise gluing and perfect post-processing of edges. PUR and airTec can be used if required. The selectable feed rate of 16-20, 25 (30) m/min enables demand-based productivity for woodworking shops and for businesses with higher performance requirements. Automation and further functionality can be added on an individual basis for these edge banding machines.

Reference images

Benefits:

- High level of flexibility – processing of high-gloss, melamine, PVC, nesting workpieces with, for example, hinge holes, solid strips or veneer

- Precise workpiece guide – belt-type top pressure unit made from steel

- Controlled chip removal – trimming tools with I system

- Intuitive operation – innovative powerTouch2 control system

- Rounding of veneer edges without tearing – four-motor profile trimming unit FF32

- Trimming quality of the highest standard – profile trimming unit FK30 with a linear servo drive

Features

- Processing of rolls of material up to 3 mm, of strips up to 12 mm alternative of solid strips up to 20 mm

- The finishing unit at the outfeed removes any glue residue and ensures the edges grip well

- Zero-joint technology with HOMAG airTec can be used

- Automatic setup for different profiles

- Easier and more precise grain calibration using an adjusting wheel

- Low energy costs plus material savings with ecoPlus

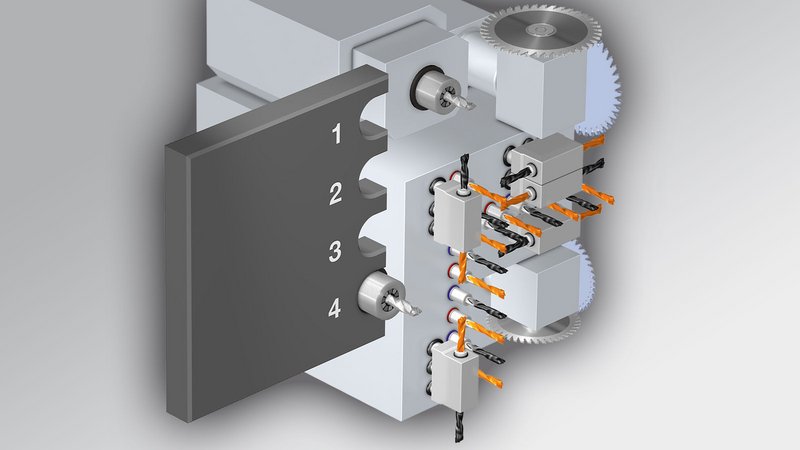

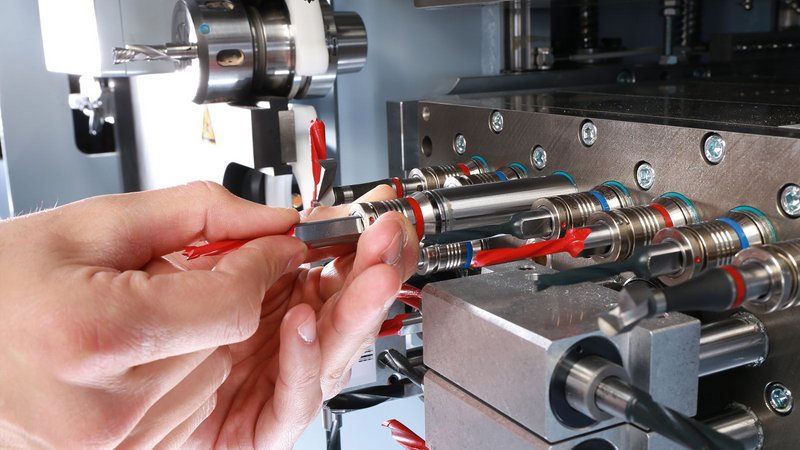

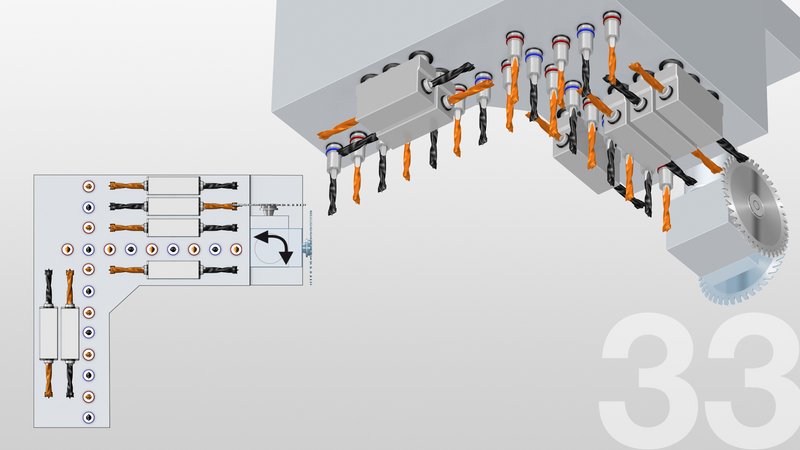

Vertical CNC Processing Center DRILLTEQ V-500

Dynamic package for powerful processing in an area of less than 10 m². The DRILLTEQ V-500 offers the next generation of compact vertical CNC technology in an area of less than 10 m². There are two powerful configurations available to choose from. Various software options improve speed and safety during processing. Automate your processes with barcode integration or workpiece return. With the dowel insertion function, you gain considerably more flexibility in your application fields.

Reference images

Benefits:

- Saves space thanks to the vertical design

- No setup times thanks to the clamping system

- Faster drilling thanks to powerful drilling equipment

- Conserves resources thanks to vacuum-free clamping technology

Features:

- powerTouch operating concept as standard

- No setup required thanks to a vacuum-free clamping system

- Plausibility check to safeguard processes

- Processes are automated with barcode integration and/or workpiece return

- Up to 36 vertical high-speed drill spindles including quick-change drill system

- Processes are accelerated thanks to automatic adjustment of size-dependent drilling

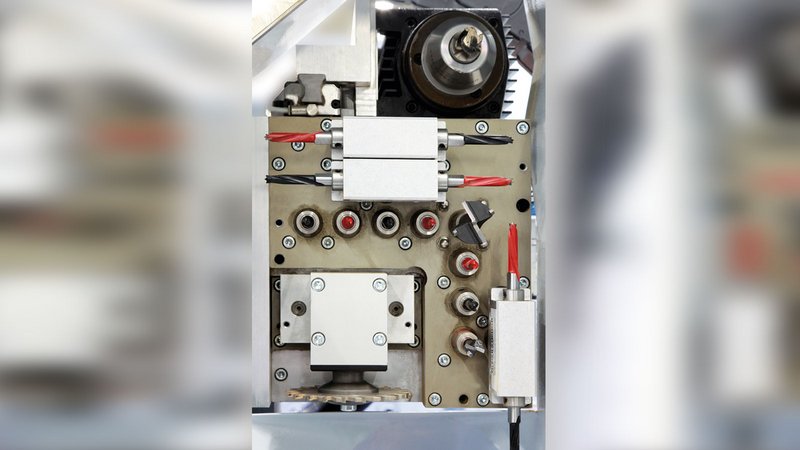

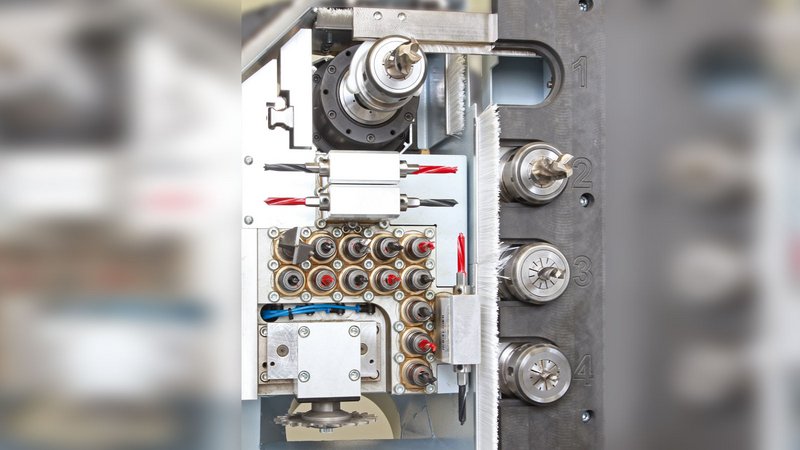

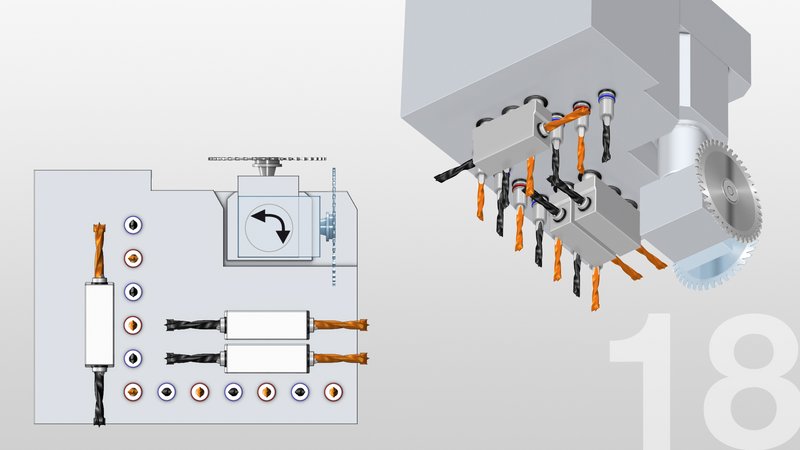

Vertical CNC Processing Center DRILLTEQ V-200

A flexible all-rounder for processing in just 5 m² These versatile machines can be used for drilling, trimming and grooving, offering the ideal solution to save you time, space, energy and money. They are particularly well-suited to just-in-time production for trade businesses and other small businesses, and for custom production in large companies.

Reference images

Benefits:

- Rapid processing saves time

- Compact design saves space

- Easy operation saves you energy

- Low price saves you money

Features

- powerTouch operating concept as standard

- No setup required thanks to a vacuum-free clamping system

- Up to 13 vertical high-speed drill spindles including quick-change drill system

- Automatic tool change magazine

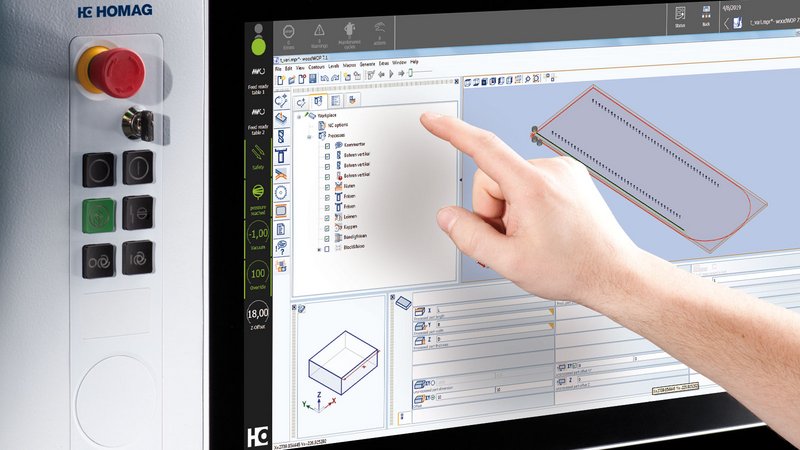

CNC Processing Center CENTATEQ P-310

Operation made easy: Working on a CNC machine has never been so easy an convenient. All of the essential functions are directly in view and mounted directly on the machine. Thanks to the large window everything is always in view. Access to the table is free, no disturbing fences are required to the left and right. Fully implemented bumpers combine productivity, security and access to the machine.

Reference images

Benefits:

- Smart support for support and maintenance using the service pad and display of machine status on smart devices.

- safeScan scanner for contact-free protection of the positioning of the automatic table and feed reduction in conjunction with the Speed Pack.

- Convenience package (option): Operating functions can be activated with a button directly on the machine. An integrated proximity scanner for intelligent pausing is included.

- Simple disposal of the offcuts and chips using the integrated chip belt. A waste box can be easily pushed onto the belt from the front.

- Deposit position to the left and right on the machine for clamping equipment.

Features:

- Switch bar instead of foot switch No searching and moving the foot switch – stops, output stroke rails and vacuum clamping can be activated easily.

- Button for program start Directly on the left and right stop profile of the machine table. The clamping status is immediately in view thanks to the multi-colored light display.

- Easy access Drill changes, service, refilling adhesive and edge changes can be carried out easily from the front side of the machine.

- Second operating terminal For optimum shuttle operation without unnecessary walking – ideal for machines with a large work field. Program selection and assignment of the machine is possible on both sides.

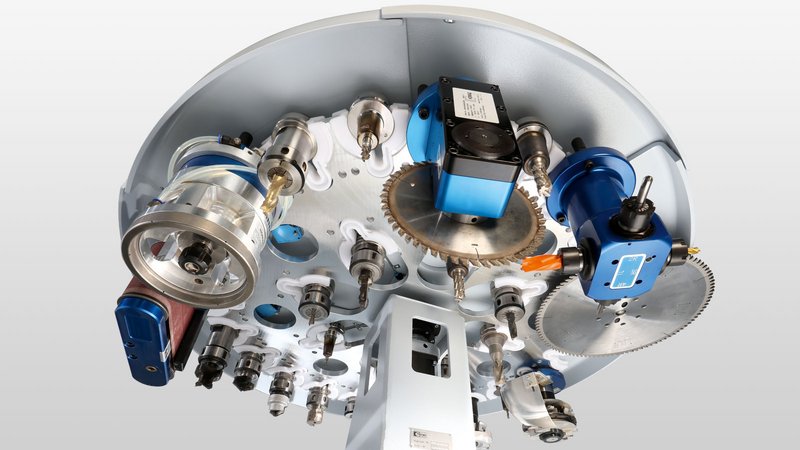

CNC Processing Center CENTATEQ P-110

Freestyle technology with 3-, 4- and 5-axis solutions This series offers high levels of performance and versatility to small and medium-sized car-pentry and joinery companies. The new machine concept is based on compact technology, a reduced installation area and operation directly at the machine. The CENTATEQ P-110 series includes 3-, 4- and 5-axis solutions for the processing of kitchen, office and solid wood furniture, as well as for the construction of stairs, windows and doors.

Reference images

Benefits:

- Freely accessible from all sides thanks to bumper safety technology

- 3-, 4- and 5-axis solutions ensure flexibility

- Fast and precise thanks to synchronous drive and linear guide system

- Innovative powerTouch operating concept

- Convenience package enables operation at the machine

Features

- Unit technology... 3-, 4- and 5-axis versions available. An all-rounder for users with demanding requirements.

- 360° access for more space... The integrated switch cabinet, bumper technology and mobile operator terminal reduce the installation area by up to 15% and ensure easy access from all sides.

- A heavyweight... Precise processing is ensured by the heavy steel welded machine frame and stable sliding gantry design.

- Convenience package Operating functions can be activated at the touch of a button directly on the machine. An integrated proximity scanner for intelligent pausing is included.

- Always in view... Optimal view into the machine with a large viewing window to ensure maximum protection for the operator.