Wirutex

Wirutex designs and manufactures PCD and carbide tools for woodworking machines

Wirutex has celebrated 40 years of business in 2020. Most of its products are GREEN. This color has become synonymous with Wirutex tools, a green that is recognized across the world. Wirutex develops high-tech products for quality craftsmanship and large-scale industry applications. A wide variety of innovative cutters and solutions for CNC work centers, Edge banding machines, CNC Panel Saws and Drilling machines.

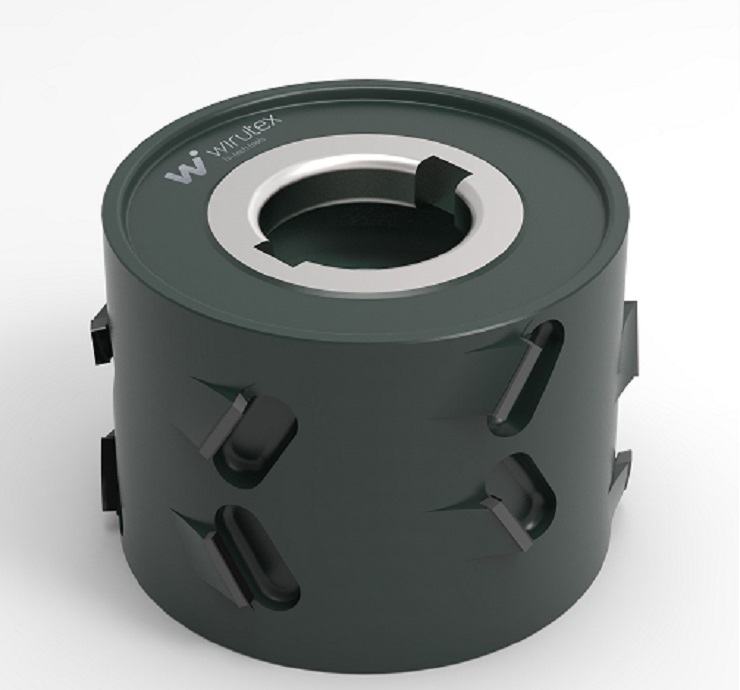

Edge Banding Tools

Wirutex and BIESSE, a well-established partnership Tools for Biesse Edge banding Machines The first supplies of Wirutex tools to be mounted on Biesse woodworking machines came out around 30 years ago, but it was only in the early years of the new century that this collaboration turned into an official partnership, with Wirutex beginning to produce tools specifically designed for Biesse machines. Wirutex currently manufactures tools tested and approved by Biesse for Edge banding and Squaring-Edge banding Machines. For Indian Market all tools required for JADE 200 , Jade 300 and Akron Series are available in stock.

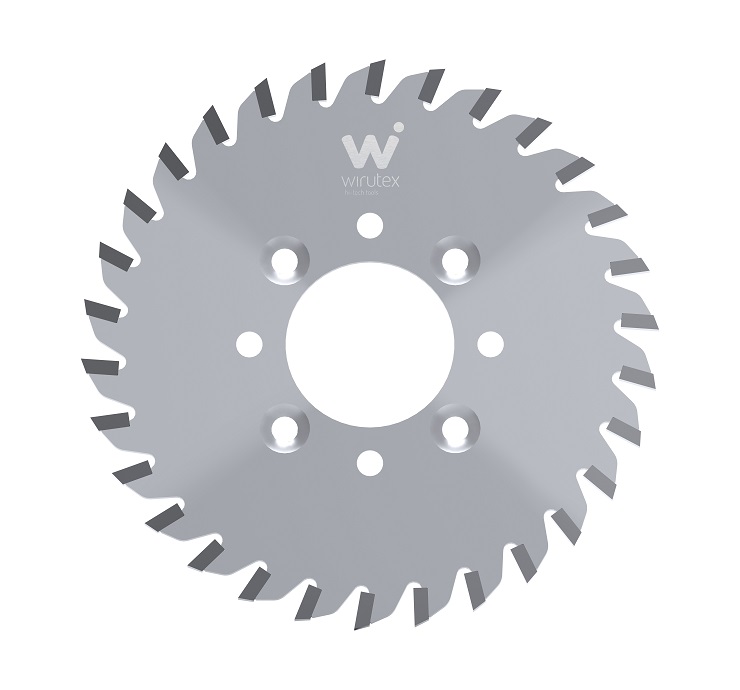

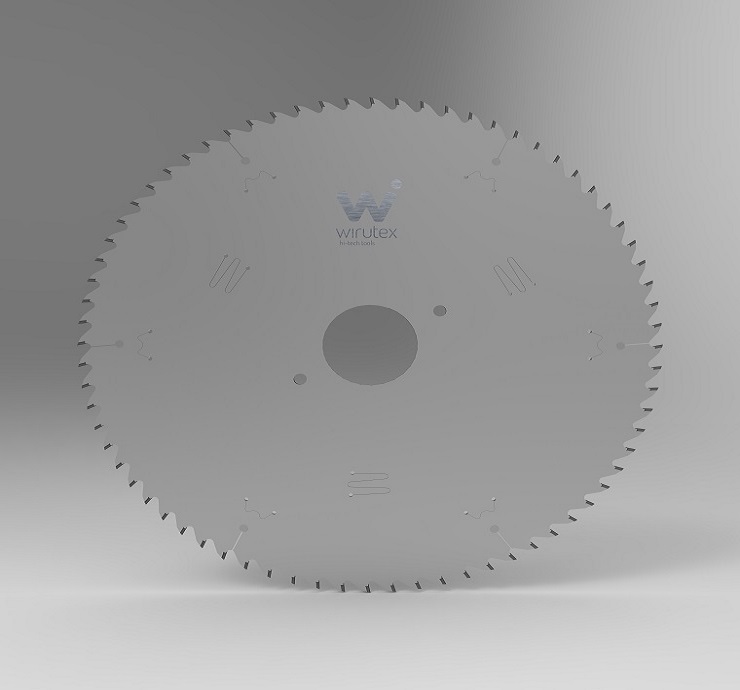

Download Brochure PDFSaw Blades

Wirutex saw blades are designed and produced using the best technology available on the market with the noise reduction slots present on the body of the blade. All our saw blades are suitable for the sectioning of either individual or stacked panels of MDF, melamine chipboard, melamine, laminated materials and other wood compounds.

Download Brochure PDFRouter bits

Wirutex hi-tech tools boasts a wide range of router bits for CNC machining centres with cutting edges made of polycrystalline diamond (DP), tungsten carbide (HW) and solid tungsten carbide (HWM). Router bits or cutters with a shank are used on CNC machining centres to carry out different types of machining operation such as profiling, sizing, boring, shaping, grooves.

Router bits made of polycrystalline diamond (DP)

Router bits made of polycrystalline diamond consist of a body in HW or HWM, on which small DP tips are braze-welded. Their long cutting life makes them particularly suitable for repeated operations on chipboard, MDF, melamine, plywood and coated plywood, HPL and CORIAN, guaranteeing high quality results throughout the whole production cycle.

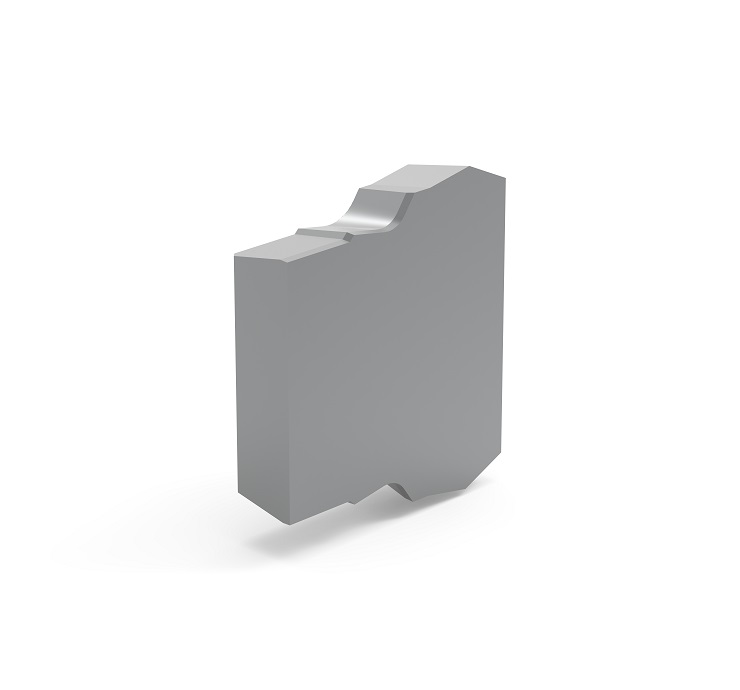

Router bits made of tungsten carbide (HW) or solid tungsten carbide (HWM)

In router bits in tungsten carbide or solid tungsten carbide, the cutting edge is made of the same material as the cutter body. They are recommended for machining wood types requiring greater chip unloading. The cutting edge of tungsten carbide tools begins to deteriorate from the very first cutting phases.

Download Brochure PDFBoring bits in polycrystalline diamond, tungsten carbide and solid tungsten carbide

Wirutex hi-tech tools boasts a wide range of boring bits for boring machines and CNC machining centres with cutting edges made of: polycrystalline diamond (DP), tungsten carbide (HW) and solid tungsten carbide (HWM) The boring bits are used on boring machines and CNC machining centres to make blind and through holes, boring operations and countersink operations.

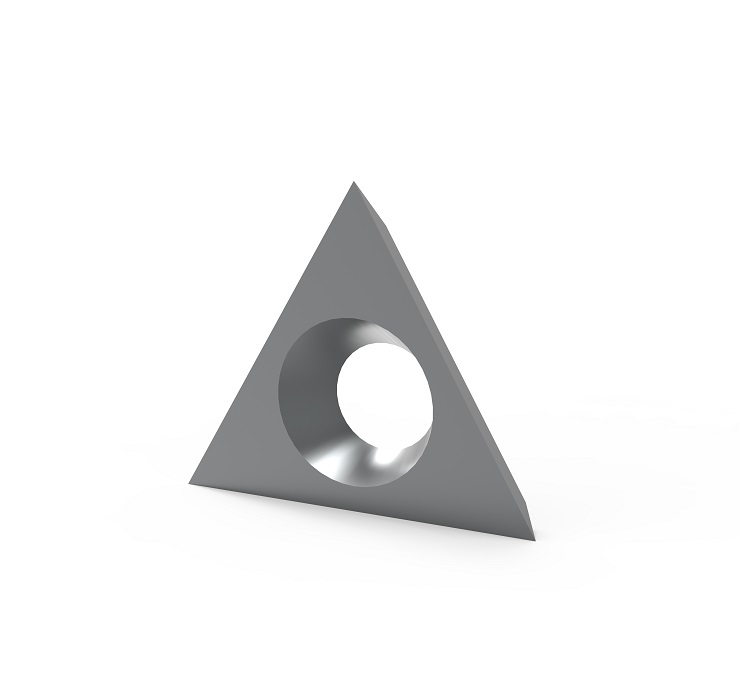

Boring bits made of polycrystalline diamond (DP)

Boring bits made of polycrystalline diamond consist of a body in HW or HWM, on which small DP tips are braze-welded. In the case of bits for hinges, the adjustable centring point may be in HW or DP.

Boring bits made of tungsten carbide (HW) or solid tungsten carbide (HWM)

In boring bits in tungsten carbide or solid tungsten carbide, the cutting edge and centering point (if present) are made of the same material as the bit body. The innovative Wirutex technology called W-Plus is used on boring bits in tungsten carbide, to guarantee a longer lifespan, better finishing and an extremely high number of boring operations.

Download Brochure PDFStart-up kits for CNC Machining Centres

Our tools are used for testing edgebanding machines and squaring-edgebanding machines, CNC machining centres and Selco panel sizing centres. The close partnership between Wirutex and BIESSE has led to the creation of a series of Start-Up Kits, tool kits designed for tooling Biesse Rover CNC machines. These kits contain the same tools used by BIESSE during the test phases on the Rover CNC machine.

The advantages of the Start-Up Kits for Biesse Rover CNCs include:

- Quicker production start-up times

- Ability to test the finish quality of the machined panels even during the testing phases

- Tests to ensure the quality and reliability of the tools recommended by Biesse, carried out directly on the machine

The kits are available in several versions:

- HT Initial start-up kit for testing of Rover machines

- HT Pro for testing and base tooling of Rover machines

- HT Nesting for nesting operations

- HT Nesting Pro for high-performance nesting operations

- NESTING Pro Universal for nesting and boring operations

Tool kits for tooling flexible cutting centres

The Nextstep Kits are designed to optimise and adapt to the end user’s machining operations, with specific tools for the various thicknesses of machined panels from 20 to 60mm. The result of close collaboration between Wirutex and Biesse, the tools in these kits are designed to test the various development phases of the Nextstep – the flexible panel sizing centre with numerical control; live tests have allowed Wirutex to flesh out its specific knowledge of cutting centres and fine-tune polycrystalline diamond cutters with a high technological content and thermal coupling chucks for enhancing the performance of these machines.

The advantages of the Nextstep Kits for Biesse Rover CNCs include:

- Quicker production start-up times

- Ability to test the finish quality of the machined panels even during the testing phases

- Tests to ensure the quality and reliability of the tools recommended by Biesse, carried out directly on the machine